- WOODWORKING

- METALWORKING

- PLASTICS / COMPOSITES

- DUST/CHIP SYSTEMS

- POSITIONERS

- SUPPLIES & ACCESSORIES

- SUPPORT

- TRAINING

- USED MACHINERY

- Sign in

-

WOODWORKING

-

METALWORKING

- PLASTICS / COMPOSITES

-

DUST/CHIP SYSTEMS

-

POSITIONERS

-

SUPPLIES & ACCESSORIES

-

SUPPORT

-

TRAINING

- USED MACHINERY

$93,416.00

| /

Flexa 47 RMA8 Edgebander

The Flexa 47 Series is a high end flexible solution for the medium to large size shop with the ability of banding tape, 1-3mm pvc, laminate and wood strips. With features typically found on solutions much more expensive, the Flexa 47 Series offers a heavy duty Edgebanding solution at an affordable price.

Units

Unit 1: Pre-milling unit

Unit 2: Glue applicator and pressure rollers

Unit 3: Edgebanding trimming guillotine

Unit 4: End Trim With 2 Tiltable motors 0-15 deg.

Unit 5: Top and Bottom Trimming via 2 motors

Unit 6: Corner rounding via 2 motors

Unit 7: Profile/ Radius Scrape

Unit 8: Glue Scraping

Unit 9: Brushing

|

TECHNICAL DATA: |

Flexa 47 rMA8 |

||

|

- Panel height |

8-60 mm |

0.3 - 2.36” |

|

|

- Coil edge thickness |

.4 - 3mm |

.015 -.12” |

|

|

- Strip edge thickness |

.4 - 12mm |

.015 - .48” |

|

|

- Max overhang top and bottom (total top and bottom) |

4 (2+2) mm |

0.16” |

|

|

- Min panel width (with min length of 210mm or 8 ¼ “) |

95mm |

3.74” |

|

|

- Min panel length (with min width of 100mm or 3 15/16 “) |

140mm |

5.5” |

|

|

- Feed speed |

12 - 16 m/ min |

39.37 – 52.5 f/min |

|

|

- Glue Tank GP-1100 |

|

|

|

|

o Power |

|

3 kW |

|

|

o Glue capacity |

1.5 kg |

3.3 lbs |

|

|

- End Trimming Unit IK/S (each) |

|

|

|

|

o Motor size |

|

.47 HP |

|

|

o Cutting speed |

|

12,000 RPM |

|

|

o Blade tilt |

|

0-15 deg. |

|

|

- Top and Bottom Trimming TT/K |

|

|

|

|

o Motor size (each) |

|

.74 HP |

|

|

o Cutting speed |

|

12,000 RPM |

|

|

- Edgescraping SCR/K |

|

3mm |

|

|

- Glue scraping unit GS/K1 |

|

0.1 – 1mm |

|

|

- Brushing |

|

|

|

|

o Motor size (each) |

|

.2 HP |

|

|

o Speed |

|

1,400 RPM |

|

SPECIFICATIONS

CA1791 FLEXA 47 RMA8 STANDARD EQUIPMENT

- Thick, welded Steel Frame

- Steel pressure beam with 2 rows rubber rollers

- Feed chain with industrial high grip rubber

- Chain on hardened steel guides

- Guides consist of one circular and one flat

- Manual adjustment of the pressure beam w/ readout

- Automatic pos. of the working units w/ reference to panel

- Mechanical digital indicators for panel thickness

- High Frequency Motors w/ Inverter

- Centralized dust extraction

- Adjustable panel support rollers

- Sound enclosure

- Lockable switch cabinet

- Equipped with

- Glue pot and edge processing magazine

- 2-Motor end trimming Unit. 0-15 deg

- 2- Motor Top and bottom trimming unit

- Edge scraping unit for 3mm

- Brushing unit

INCLUDED FEATURES

CA4788 Execution complying to US regulations (UL/CSA) Safety Standards

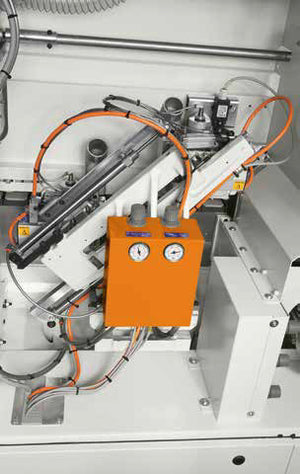

CA2074 Anti-adhesive Unit “RA” to avoid glue deposits on top and bottom surfaces

CA4533 Mega 300 TS Control

CA3624 Diamond Tools on Pre Mill H=64 Z= 2+2

CA4048 Spray Mist Device for edge finishing improves panel cleaning and polishing of the applied edge

CA5001 Spare GP/1100 Glue Tank

CA5555 Glue Scraping Unit “GS/K1”

CA4544 Brushing/ Buffing Unit “BFK

ELECTRICAL DATA:

E-Stop on main control panel

230 V – 3 Ph – 60 Hz. 37 Amps

MACHINE FEATURES

In feed and construction

- Industrial grade in feed system with high grip, interchangeable rubber pads.

- Guided by a chain for accurate feeding and long lasting perfection

- Thick, Steel top pressure beam complete with two rows of rubber coated wheels.

- Robust panel support which can be extended according to the size of the parts

MEGA 300 TS Controller

- Ergonomic positioning

- 12”Graphic Color Display w/ multi language selection

- Glue temp. control w/ temp

- Graphic simulation of machining for each side of panel

- Graphic representation of each station status on/off

- Stores 100 customizable edging programs

- Instant program recall of 6 favorite programs

- On board diagnostics

- Partial and absolute statistical info

Pre-milling unit

- Two cutter heads with automatic timing

- Independent high frequency motors with

- Stock removal determined by infeed fence with digital display

- Timed blower to clean the machined surface

- Diamond tools

2.4 hp each. Tools D=100mm H=49mm

Max stock removal is H=45mm / 55mm ²

Anti- Adhesive Unit RA

- Perfect cleaning of the panel

- Prevents glue from sticking to the top and bottom surfaces

Gluing Unit GP/1100

- 4 pressure rollers (1st driven, 2nd and 3rd with opposed conicity and 4th cylindrical)

- Teflon coated quick release glue pot

- Automatic glue temperature regulator to reduce glue temperature if machine is not in use to reduce glue heat time

- Dual glue temperature adjustments for working with two different temperatures

- Automatic recovery of glue

- Automatic loader for strips

4 HP Power. 53oz Capacity

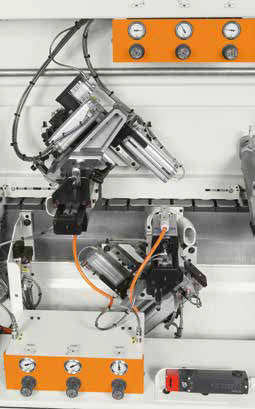

End Trimming Unit IK/S

- 2 Independent high frequency motors w/ blades

- Pneumatic tilting of the saw blade 0 – 15 deg. from control panel

- Units slide on THK guideways

- Mounted to the base for vibration free machining

12,000 RPM and .5 hp each

Trimming Unit “TT/K”

- 2 Independent high frequency motors

- Vertical revolving copy devices and front copy pads for accurate positioning

- Dust extraction hood

- 3mm tooling standard

12,000 RPM and .4 hp each

Corner Rounding Unit “A/2”

- For automatic rounding of PVC/ ABS edging with radius of 1 – 3mm

- High frequency motors

- Two pneumatic working positions chosen from the controller

- Vertical and frontal copying device for adjustment of cutting point on the panel

- Supplied with 3mm diamond tooling

- Pneumatic exclusion selected from the controller

Edge Scraping Unit “SCR/K”

- For finishing 1mm – 3mm PVC/ ABS edging

- Front and vertical copy devices for accurate positioning of the knives

- Complete with digital mechanical readouts for accurate positioning and adjustment

- Dust extraction

- Supplied with 3mm tooling

Spray mist device for edge finishing

- Prepares edge and surface for scraping and buffing

- Improves finish quality

Glue Scraping Unit GS/K1

- Eliminates excess glue between panel and edge

- Eliminates small edging overhang (0.1 – 1mm)

- 2 Pairs of vertical rotating copiers

- Air blowers on both cleaning knives

- Self-adjusting throwaway knives

Buffing Unit “BFK”

- For cleaning panel to reduce manual labor of finished parts

- 1,400 RPM each

- .20 hp motor each