- WOODWORKING

- METALWORKING

- PLASTICS / COMPOSITES

- DUST/CHIP SYSTEMS

- POSITIONERS

- SUPPLIES & ACCESSORIES

- SUPPORT

- TRAINING

- USED MACHINERY

- Sign in

-

WOODWORKING

-

METALWORKING

- PLASTICS / COMPOSITES

-

DUST/CHIP SYSTEMS

-

POSITIONERS

-

SUPPLIES & ACCESSORIES

-

SUPPORT

-

TRAINING

- USED MACHINERY

Free

| /

Description

General Description: The Langzauner LZ5-2E Veneer Saw is a high-performance, precision cutting solution designed to meet the needs of industries that require splinter-free, joint-tight cuts in a variety of materials, including veneers, plastics, plastic-coated panels, acrylics, wood materials, light metals, and cardboard. This saw combines advanced features like automatic saw blade adjustment, electromotorical feed, and pneumatic systems to deliver consistently accurate results, making it ideal for both small and large cutting tasks in professional workshops.

Upgrade Your Workshop with the Langzauner LZ5-2E Veneer Saw!

The Langzauner LZ5-2E Veneer Saw is designed for high-precision, splinter-free cutting, ensuring that veneer, plastics, and acrylics are processed with ease and accuracy. With its advanced pneumatic adjustments, automatic saw blade adjustments, and digital measuring system, the LZ5-2E is the ultimate solution for professional workshops needing versatile, reliable cutting performance.

Contact us today to learn more or request a personalized quote!

Features

Key Features:

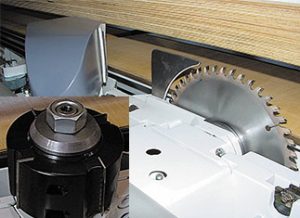

- Milling Unit for Perfect Cutting Kerf: Equipped with a milling unit to create perfect cuts with minimal material loss, ensuring smooth and clean edges for various materials.

- Electromotorical Feed: Features an electromotorical feed system that ensures smooth material handling, offering adjustable feed speeds for various materials and thicknesses.

- Double Linear Guiding: Double linear guiding provides precision movement for a consistent cutting process, ensuring accuracy and smooth operation.

- 4 HM Inserts: Equipped with four tungsten carbide (HM) inserts, this saw offers durable, long-lasting cutting performance with minimal maintenance.

- Pneumatic Saw Blade Adjustment (Automatic): The automatic pneumatic saw blade adjustment allows for easy adjustments within a 2 mm range, making it perfect for cutting various material thicknesses.

- Rack and Pinion Compensator: This compensator prevents the pressure beam from tilting, ensuring the material remains perfectly aligned for accurate cuts.

- Tools and Filter Pressure Regulator: The saw comes equipped with tools and a filter pressure regulator, ensuring efficient and smooth operation during extended cutting sessions.

- Pneumatically Lifting and Lowering Saw and Milling Unit (3 Stages): The saw and milling units can be raised and lowered in three stages for easy adjustment based on the material and cutting requirements.

- Movable Supporting Table: The supporting table can be moved manually or with pneumatic control, providing ease of material handling, especially when using the milling unit.

- Format Table: The format table allows for processing veneers with parallel stops (parallel guides), inserted tape measures, and pneumatic locks, ensuring consistent and accurate cutting.

- Pneumatic Lowerable Stops for Stop Depth of 800 mm: The pneumatic stops can be lowered for stop depths of 800 mm, providing precision when cutting larger materials.

Advantages

Advantages:

- Precision Cutting: The automatic saw blade adjustment, milling unit, and pneumatic pressure beam provide precise cuts, especially on delicate materials like veneers and plastics.

- Efficiency and Flexibility: The electromotorical feed, pneumatically adjustable saw and milling units, and movable supporting table make the LZ5-2E suitable for high-efficiency operations with minimal downtime.

- Enhanced Safety: With transparent safety covers and a splinter shield, the LZ5-2E ensures safe operation while maintaining optimal visibility of the cutting process.

- Wide Cutting Range: The saw can handle a range of materials and thicknesses, making it perfect for industries requiring versatility in their cutting operations.

Benefits

Benefits:

- Increased Productivity: The automated features like pneumatic adjustments and electromotorical feed streamline the cutting process, resulting in faster setup times and consistent, high-quality cuts.

- Cost-Effective Operations: The saw’s ability to produce accurate, splinter-free cuts with minimal material waste translates into significant long-term savings on materials.

- Durability and Reliability: With high-quality components like HM inserts, pneumatic systems, and precision guiding, the LZ5-2E is built for long-lasting reliability in high-demand environments.

- Versatile Applications: The LZ5-2E is suitable for a variety of materials, including wood, plastics, acrylics, and light metals, providing flexibility for different industries.

Technical Data

Technical Data:

- Cutting and Milling Height: 40 mm

- Motor Power (Saw): 2.2 kW

- Rotation Speed (Saw Blade): Approx. 10,000 rpm

- Saw Blade Diameter: Ø 200 mm

- Motor Power (Milling Unit): 1.1 kW

- Rotation Speed (Milling Cutter): Approx. 10,500 rpm

- Milling Cutter Dimensions (Ø x H x iØ): 85 / 50 / 30 mm

- Motor Power (Feed): 0.18 kW

- Feed Speed: 2-25 m/min

- Extraction Diameter: Ø 140 mm

- Air Velocity: ≥ 20 m/s

- Volume Flow (at 20 m/s): 1000 m³/h

- Suction Vacuum (at 20 m/s): 1780 Pa

- Required Air Pressure: 6 bar

- Total Connected Load: 3.5 kW

- Operating Current: 10 A

- Operating Voltage: 3 x 400 V + N + PE / 50 Hz

- Cutting and Milling Lengths: 3050 mm, 3500 mm, 4000 mm

-

Required Space (without format table):

- 3050 mm length: Approx. 4550 x 1050 mm

- 3500 mm length: Approx. 4950 x 1050 mm

- 4000 mm length: Approx. 5450 x 1050 mm

-

Required Space (with all options):

- 3050 mm length: Approx. 4550 x 1500 mm

- 3500 mm length: Approx. 4950 x 1500 mm

- 4000 mm length: Approx. 5450 x 1500 mm

-

Weight (without format table):

- 3050 mm length: Approx. 950 kg

- 3500 mm length: Approx. 1050 kg

- 4000 mm length: Approx. 1150 kg

-

Weight (with all options):

- 3050 mm length: Approx. 1150 kg

- 3500 mm length: Approx. 1250 kg

- 4000 mm length: Approx. 1350 kg

Options

Optional Equipment:

- Movable Supporting Table: Can be manually movable or pneumatically controlled, allowing for easy material handling.

- Format Table: Ideal for processing veneers with parallel stops and pneumatic locks, ensuring consistent cutting.

- Digital Measuring Display: Provides fast, accurate adjustments with easy-to-read display and offset changeover.

- Parallel Stop (Adjustable): Ensures precise cuts with adjustable one-stage or double-stage lowering.

- Chipping Unit: Ensures cleaner cuts and minimizes waste.