- WOODWORKING

- METALWORKING

- PLASTICS / COMPOSITES

- DUST/CHIP SYSTEMS

- POSITIONERS

- SUPPLIES & ACCESSORIES

- SUPPORT

- TRAINING

- USED MACHINERY

- Sign in

-

WOODWORKING

-

METALWORKING

- PLASTICS / COMPOSITES

-

DUST/CHIP SYSTEMS

-

POSITIONERS

-

SUPPLIES & ACCESSORIES

-

SUPPORT

-

TRAINING

- USED MACHINERY

Free

| /

Description

General Description:

The HotMaster is an advanced automatic hot gluing machine designed specifically for the application of hot-melt adhesives. Equipped with 4 rollers and 4 motors, this machine offers high-efficiency glue application for a variety of materials, including veneers, plastics, plastic-coated panels, acrylics, wood materials, light metals, and cardboard. The HotMaster guarantees splinter-free, joint-tight gluing with exceptional precision, ideal for businesses that require consistent, high-quality adhesive applications for large-scale production.

Upgrade Your Workshop with the HotMaster Hot-Melt Gluing Machine!

The HotMaster is the ultimate solution for high-efficiency hot-melt adhesive applications. With automatic roller adjustment, precise glue application, and advanced PLC controls, the HotMaster ensures optimal results for businesses requiring reliable, high-quality gluing in their production lines.

Contact us today to learn more or request a personalized quote!

Features

Key Features:

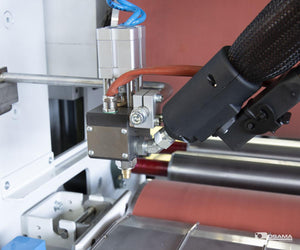

- 4 Rollers and 4 Motors: The HotMaster is equipped with 4 independent motors for each roller, providing superior control over glue application and enabling efficient and precise handling of materials.

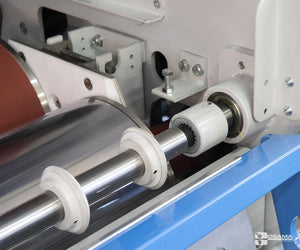

- Motor-Driven Rollers with Self-Centering Guides: Features motor-driven rollers with self-centering guides, ensuring smooth and consistent material feed without manual adjustments.

- Hot-Melt Adhesive Application: Specifically designed for hot-melt adhesives, the HotMaster provides perfect application of glue, ensuring uniform coating and reducing waste.

- Internal Heating System for Rollers: The rollers are equipped with a diathermic oil heating system, separately controlled for each roller, maintaining the ideal temperature for optimal adhesive performance.

- Adjustable Glue Application: The glue application area can be reduced for specific jobs, allowing operators to adjust the adhesive coverage to match the material size and glue thickness requirements.

- Automatic Lifting of the Upper Roller: The upper roller can be automatically raised to set the material thickness, with digital position reference to ensure precise control of glue application.

- PLC Control System: The PLC allows for easy setup and adjustments, including repeating spreading values from previous jobs, enhancing operational efficiency.

- Precise Speed Control: The feed speed is controlled by inverters, allowing for independent adjustment for each roller to ensure optimal gluing results for varying material types.

- Motorized Introducer and Extractor: Features motor-driven introducers and extractors to simplify panel handling, allowing for smooth entry and exit of panels with a minimum length of 600 mm.

- Automatic Cleaning System: The machine features an automatic cleaning system for the rollers during maintenance and shift changes, ensuring continued performance without manual intervention.

Advantages

Advantages:

- Consistency and Precision: With its 4 motorized rollers, automatic glue application, and adjustable glue spread, the HotMaster ensures consistent results with minimal variation between applications.

- Enhanced Efficiency: The ability to adjust glue application area and the digital controls significantly reduce waste, making the machine highly efficient and cost-effective for high-volume operations.

- Superior Adhesive Performance: The internal heating system for rollers ensures that the hot-melt adhesive is applied at the right temperature, enhancing adhesion and reducing glue waste.

- Ease of Use: With simple operation, large digital displays, and the PLC control system, the HotMaster is easy to set up and operate, allowing for quick adjustments and minimal downtime.

Benefits

Benefits:

- Higher Productivity: The HotMaster increases throughput by reducing setup times, improving material handling efficiency, and ensuring consistent adhesive application for faster production cycles.

- Long-Term Cost Savings: The automatic glue application and reduced adhesive waste lead to significant cost savings over time, making the HotMaster a smart investment for businesses.

- Versatility in Application: The machine can handle a wide range of materials and adhesives, making it suitable for various industries that require precise gluing applications.

Technical Data

Technical Data:

- Working Widths: Available in 1400 mm, 1600 mm, 1800 mm, 2000 mm, 2200 mm widths

- Glue Application Range: Can be reduced for specific jobs to optimize glue usage

-

Roller Diameter:

- Gluing Rollers: 250 mm

- Dosing Rollers: 210 mm

- Working Panel Thickness: 0-100 mm

- Motor Power (Gluing Rollers): 1.1 kW per roller

- Motor Power (Feeding): 0.9 kW

- Voltage: 400V/50Hz

- Maximum Glue Application Speed: 20 m/min

-

Weight (Approx.):

- 1400 mm Width: Approx. 950 kg

- 1600 mm Width: Approx. 1000 kg

- 1800 mm Width: Approx. 1050 kg

-

Dimensions (L x W x H):

- 1400 mm Width: Approx. 2500 x 1400 x 1800 mm

- 1600 mm Width: Approx. 2600 x 1600 x 1800 mm

Options

Optional Equipment:

- Motorized Extractor and Introducer: Simplifies the entry and exit of panels for smooth operation.

- Digital Measure Display: Allows for fast, accurate control of the glue application depth.

- Chipping Unit: Reduces material waste and ensures smoother, more efficient cutting.

- Motorized Table Adjustment: Provides precise, motorized control for panel placement and handling.

- Additional Glue Heating System: Optional system for enhanced roller heating, improving performance during extended production runs.