- WOODWORKING

- METALWORKING

- PLASTICS / COMPOSITES

- DUST/CHIP SYSTEMS

- POSITIONERS

- SUPPLIES & ACCESSORIES

- SUPPORT

- TRAINING

- USED MACHINERY

- Sign in

-

WOODWORKING

-

METALWORKING

- PLASTICS / COMPOSITES

-

DUST/CHIP SYSTEMS

-

POSITIONERS

-

SUPPLIES & ACCESSORIES

-

SUPPORT

-

TRAINING

- USED MACHINERY

Free

| /

Description

Langzauner LZ5-2 Veneer Saw

General Description: The Langzauner LZ5-2 Veneer Saw is a high-performance machine designed for splinter-free, joint-tight cutting of a variety of materials, including veneers, plastics, plastic-coated panels, acrylics, wood materials, light metals, and cardboard. With a combination of saw and milling units, automatic adjustments, and advanced features like digital measuring displays, the LZ5-2 delivers unmatched precision and efficiency. Whether you're cutting complex materials or simple wood panels, the LZ5-2 provides excellent results with every pass.

Upgrade Your Workshop with the Langzauner LZ5-2 Veneer Saw!

The Langzauner LZ5-2 Veneer Saw is a perfect solution for businesses requiring high-precision, splinter-free cuts on a variety of materials. With its automated features, digital measuring system, and pneumatic adjustments, this saw is ideal for high-efficiency operations in industries where precision and speed are crucial.

Contact us today to learn more or request a personalized quote!

Features

Key Features:

- Milling Unit for Perfect Cutting Kerf: The saw comes equipped with a milling unit, ensuring a perfect kerf for splinter-free cuts, even on delicate materials like veneer and acrylic.

- Manual Feed Handlebar: The manual feed handlebar provides precise control over material feeding during cutting, giving the operator full command of the operation.

- Double Linear Guide: This double linear guiding system ensures smooth, accurate movement and alignment during cuts, providing optimal cutting results across a variety of materials.

- 4 HM Inserts: The machine features four high-quality tungsten carbide inserts, ensuring durability and longevity of the saw blade.

- Pneumatic Saw Blade and Milling Unit Adjustment: The saw and milling units can be pneumatically lifted and lowered in three stages, allowing for precise adjustments based on material thickness.

- Pneumatic Pressure Beam: The automatic pneumatic pressure beam holds the material securely during cutting, ensuring consistent results with minimal effort.

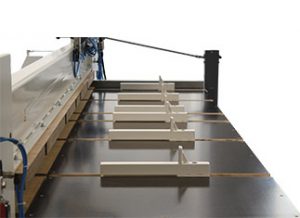

- Format Table: The format table is designed for precise processing of veneers, with pneumatically lowerable stops for a stop depth of 800 mm, allowing quick adjustments for various materials and cutting tasks.

- Digital Measuring Display (Optional): The electronic measuring display offers accurate stop depth adjustments, simple operation, and offset changeovers, ensuring fast and precise cuts every time.

- Parallel Stop (Adjustable): The parallel stop can be one-stage or double-stage lowerable, ensuring fast and efficient material handling during cutting operations.

- Chipping Unit (Optional): The chipping unit reduces material waste and ensures cleaner cuts, enhancing overall operational efficiency.

Advantages

Advantages:

- Enhanced Precision and Efficiency: The combination of saw and milling units, automatic pneumatic adjustments, and digital measuring displays ensures that cuts are consistently accurate, smooth, and fast, even when processing large volumes of material.

- Versatile Material Handling: Capable of cutting various materials, including wood, plastics, acrylics, and light metals, the LZ5-2 is perfect for businesses requiring flexibility in their cutting operations.

- Automation and Safety: With features such as the pneumatic pressure beam and transparent safety covers, the LZ5-2 enhances operator safety while minimizing the need for manual intervention.

- Space-Saving Design: The compact design of the LZ5-2 ensures efficient operation in small or busy workshops without compromising performance.

Benefits

Benefits:

- Increased Productivity: The automated adjustments, pneumatic lifting and lowering system, and digital measuring display reduce setup time and manual labor, increasing throughput and efficiency.

- Cost-Effective Operations: By reducing material waste, improving cutting accuracy, and ensuring clean results, the LZ5-2 helps businesses save on both materials and labor costs.

- Reliability and Longevity: Built with high-quality components such as HM inserts and precision guides, the LZ5-2 is designed for long-term reliability, ensuring minimal maintenance and extended service life.

Technical Data

Technical Data:

- Cutting and Milling Height: 40 mm

- Motor Power (Saw): 2.2 kW

- Rotation Speed (Saw Blade): Approx. 10,000 rpm

- Saw Blade Diameter: Ø 200 mm

- Motor Power (Milling Unit): 1.1 kW

- Rotation Speed (Milling Cutter): Approx. 10,500 rpm

- Milling Cutter Dimensions (Ø x H x iØ): 85 / 50 / 30 mm

- Motor Power (Feed): 0.18 kW

- Feed Speed: 2-25 m/min

- Extraction Diameter: Ø 140 mm

- Air Velocity: ≥ 20 m/s

- Volume Flow (at 20 m/s): 1000 m³/h

- Suction Vacuum (at 20 m/s): 1780 Pa

- Required Air Pressure: 6 bar

- Total Connected Load: 3.5 kW

- Operating Current: 9 A

- Operating Voltage: 3 x 400 V + N + PE / 50 Hz

- Cutting and Milling Lengths: 3050 mm, 3500 mm, 4000 mm

-

Required Space (without format table):

- 3050 mm length: Approx. 4500 x 1150 mm

- 3500 mm length: Approx. 4950 x 1150 mm

- 4000 mm length: Approx. 5450 x 1150 mm

-

Required Space (with all options):

- 3050 mm length: Approx. 4500 x 1600 mm

- 3500 mm length: Approx. 4950 x 1600 mm

- 4000 mm length: Approx. 5450 x 1600 mm

-

Weight (without format table):

- 3050 mm length: Approx. 900 kg

- 3500 mm length: Approx. 1000 kg

- 4000 mm length: Approx. 1100 kg

-

Weight (with all options):

- 3050 mm length: Approx. 1100 kg

- 3500 mm length: Approx. 1200 kg

- 4000 mm length: Approx. 1300 kg

Options

Optional Equipment:

- Rack and Pinion Compensator: Prevents the pressure beam from tilting, ensuring smooth and accurate cuts every time.

- Movable Supporting Table: Can be manually movable or pneumatically controlled, providing flexibility for handling larger materials.

- Digital Measuring Display: Ensures fast, accurate stop adjustments, with large digit height for easier operation.

- Parallel Stop: Adjustable for one-stage or double-stage lowering, enabling quick adjustments for varying material sizes.

- Chipping Unit: Reduces material waste and enhances cutting quality.