- WOODWORKING

- METALWORKING

- PLASTICS / COMPOSITES

- DUST/CHIP SYSTEMS

- POSITIONERS

- SUPPLIES & ACCESSORIES

- SUPPORT

- TRAINING

- PRE-OWNED MACHINES

- Sign in

-

WOODWORKING

-

METALWORKING

- PLASTICS / COMPOSITES

- DUST/CHIP SYSTEMS

-

POSITIONERS

-

SUPPLIES & ACCESSORIES

- LAMELLO

- BISCUIT JOINERS

- BISCUITS & PLATES

- P-SYSTEM CONNECTORS & KITS

- P-SYSTEM ACCESSORIES

- CABINEO CONNECTORS & KITS

- CABINEO ACCESSORIES

- ABRASIVES

- ADHESIVES

- BLADES

- CLASSICAL MACHINERY TOOLING

- CNC ACCESSORIES

- CNC ROUTER BITS

- DRILL/BORING BITS

- DOWELS

- DUST COLLECTION ACCESSORIES

- EDGEBANDER TOOLING

- GASKETING

- GREASE AND LUBRICANTS

- SAW STOP PARTS AND ACCESSORIES

-

SUPPORT

-

TRAINING

-

PRE-OWNED MACHINES

$89,206.00

| /

To see the entire AXO line of beam saws and options CLICK HERE FOR BROCHURE

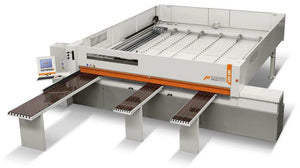

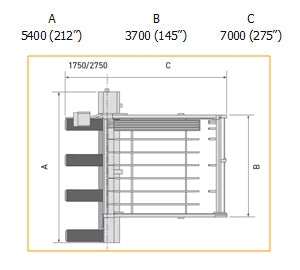

CASADEI AXO 200/33

Front Load Panel Saw

|

STANDARD TECHNICAL FEATURES: |

||

|

Ripping capacity |

3300 mm |

129” (10.8 ft) |

|

Useable pusher stroke |

3200 mm |

126” (10.5 ft) |

|

Worktable height |

950 mm |

37.4” |

|

Main blade projection |

70 mm |

2.75” |

|

Main blade power |

9 kW |

14.5 HP |

|

Main blade diameter |

320 mm |

12.6” |

|

Main blade arbor |

80 mm |

3.15” |

|

Main blade rotation speed |

4600 rpm |

|

|

Scoring blade power |

1.5 kW |

2 HP |

|

Scoring blade diameter |

160 mm |

6.3” |

|

Scoring blade arbor |

55 mm |

2.16” |

|

Scoring rotation speed |

7560 rpm |

|

|

|

|

|

|

Saw carriage speed |

6 - 60 mpm |

19 – 200 fpm |

|

Maximum pusher speed |

60 mpm |

200 fpm |

|

Number of grippers/ clamps |

5 (standard) + 2 |

|

|

Dust extraction outlets @ diameter |

2 @ 120 mm |

5” |

|

|

1 @ 100 mm |

4” |

|

Dust extraction velocity |

28 mps |

5500 fpm |

|

|

1.13 m3/s |

2400 cfm |

|

Compressed Air |

6 Bar |

90 psi |

|

|

300 Nl/min |

11 cfm |

|

Electrical Service |

230 V - 3 Ph - 60 Hz |

55 Amp |

STANDARD MACHINE SPECIFICATIONS

-

Machine Frame

- Heavy plate-steel table with double tubular structure

- Heavy plate steel saw bed with Phenolic top

- Rear table extruded aluminium structure with Phenolic top

- Support rollers of non-scratch UHD

- Safety fences around rear of the machine

-

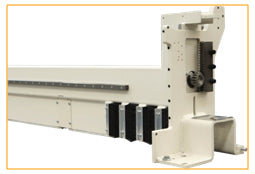

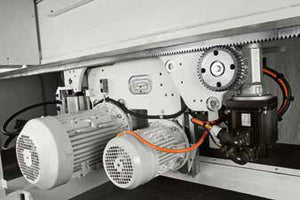

Saw Carriage

- Independent drives, main and score blade using prismatic guides.

- Vertical adjustment over THK guides

- Driven by precision Rack and Pinion

- Movement of carriage on “V” Grove rollers riding on hardened steel guide rails (5 Yr. Warranty)

- Saw carriage stroke toward cross-cutting fence

-

Pressure Beam

- Fabricated from steel plate

- Slotted for grippers

- ensures exact panel positioning

- Double rack and pinion system for movement

- Large pneumatic cylinders at both ends

-

Double dust collection points

- Top connection for dust removal from pressure beam

- Bottom connection for chip removal from saw carriage

-

Operator controls (PC)

- Mounted on Left Side

- 21.5” Color Touchscreen Monitor

- Intel Pentium Processor 2.9 Ghz with Windows platform

- CUTI optimization software

- Std, keyboard

- Label printer (optional)

- Single USB port 3.0

- 8 GB RAM

- 256 GB Hard Drive

- Mounted on Left Side

-

Safety

- Safety fence system with slotted or plastic window

- Safety screen

-

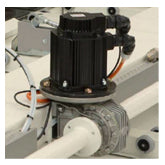

Full length powered pusher

- Central drive system

- Two heavy duty torsion bars

- Electronically adjustable

- The pusher travels in structural H-beams

- Pusher feed is by two high precision rack & pinions

- 6 clamps for panel clamping

-

NC positioning of material pusher

- AC brushless servo motor

- Inverter control for variable speed via PC

- Linear magnetic measurement system

-

Automatic Side Aligner

- Automatic positioning w/ pneumatic cylinder

- Minimum width: 60 mm (2.36”)

- Maximum width: 1200 mm (25”)

- The side aligner slides over a THK guide

-

Main electrical cabinet with:

- Dust-proof cabinet (IP 55/NEMA 12) with lockable main disconnect

- Overload protections for motors and controls

- Interlocking safeties, emergency bar and blade change cover

- Control voltage 110 Volts for control board, electronic control and low voltage signals

- PC with EASY2CUT Software:

|

“EASY2CUT” Software |

|

|

• Control and programming system including: Console with integrated PC Smart Control equipped with: (minimum features): - Industrial PC “fanless - Protection class IP53 (only on front IP65) - LCD colour display: 21,5”, Full HD; 16/9; LED backlighting; 10 touches capacitive multi touch screen; viewing angle 176°H, 160°V “zero pixel defect” - Intel Pentium processor; 2,9 GHz - RAM memory: 8 GB - Hard disk: 256 GB - Operating system: Windows - Querty keyboard with English layout - Wired mouse - Ethernet socket RJ45 - Single, external USB port. 3.0 - Nominal operating temperature: from +5°C to +35°C - Software Easy2Go Cut Easy2Go Cut with following functions: Working modes • Manual mode for axis movements • Automatic mode: execution of cutting programs and/or lists of cutting • Semi-automatic mode: execution of different measures programmable Advanced Editor of cutting pattern • Advanced editing system for cutting pattern in WYSIWYG mode for management of longitudinal, transversal cuts, pre-cuts, trim cuts and second level cuts. Advanced file browsing system • The file browser Easy2Go cut allows to manage/start/copy/delete the machine programs. A real-time preview function allows to check in browser each cutting pattern. Control Paddle (screen) • Virtual pushbutton control panel Management of tools and materials archives • The materials and tools archives allows to archive each item with its operating and execution parameters. Machine simulator • Possibility to view the graphical simulation in real time with indication of the cutting dimensions and timing. Reporting system • The control records every single action/event in the machine and makes available production reports, events, alarms and maintenance. Maintenance support • Easy2Go cut reports operations to be carried out on the machine, with periodic notifications connecting them to the relevant procedure. Diagnostic system • Easy2go Cut detects and displays alarms and warnings, offering help for elimination of the current error. User management • Easy2Go records the activities of each operator registered in the system Label editor • The label editor allows creation and printing of labels even with bar codes directly on the machine. The operator can enter new data on the label or transfer them from the Perfect Optimiser Plus or Easy Cut Pattern Optimiser database. Information can be printed with a text or bar codes. In addition, it is possible to add imagines or lines. Additional functionalities included in specific modules make Easy2go Cut extremely flexible for pieces labelling, with the possibility of previews during editing and execution pattern, enabling elaboration of statistical information even more detailed. Measuring system • Measuring unit: millimetres-tenths or inches-thousandths Available languages • Operator's interface available in the following languages: Italian, English, French, Spanish, German Note: The description of the control system includes certain functions Optimization software for creating cutting programs starting from the raw panel up to the finished panel. • Types of formats for each material: 5 • Max. no. of lines per program: 30 • Max. no. of pieces per line: 500 • Cutting level: longitudinal (Y), transversal (X) third level (Z) • Management pre-cut • Management off-cuts stock interfaced with Easy2Go Cut • Statistic report: % order waste, number of used panels, number of produced panels • Graphic visualisation of product schemes • 8 import fields for label information (material, type of colour, thickness, width, length, code, description, 4 edges fields) • Panel stock: 2 • Import from XLS file >= Excel 97. Allows import of Excel files with data related to the pieces of a cutting list of only one material (code, description, length, width, quantity, grain, 4 edge fields) TELESERVICE system service via internet Service free of charge for the duration of the warranty |

|

INCLUDED FEATURES:

CA1797 AXO 200/3300

CA8244 Different voltage/frequency 220/230V 50/60Hz –Neutral connection

STD. Saw carriage driven by rack and pinion

CA8247 Pusher stroke 3300 mm (129”)

CA8245 Air Conditioner for the electrical cabinet

CA3218 Fixed air floatation table w/ crosscut fence 2500 x 600mm (98 x 24”)

CA8226 2 front movable air floatation tables on wheels 1500 x 400mm (59x24”)

CA7251 Centralized blower fan for air floating tables

STD. Saw and scoring blade flanges with pneumatic locking

STD. Automatic Star Delta Starter

CA8253 Pusher positioning, magnetic strip

CA8255 Two Additional Clamps. 7 total clamps

WARRANTY:

Seller warrants, for a period of one (1) year beginning on the date the Machinery is accepted, that the Machinery will be free of defects in workmanship and materials, excluding belts, bearings, and common electrical parts, which carry a six-month warranty. This warranty does not include parts consumed during normal operation (wearable items), working units, or maintenance required in the ordinary course of operation. Seller shall warrant any replacement spare parts and accessories installed pursuant to this warranty for the period of ninety (90) days.

TOOLING:

Tooling, including blades, is not included unless noted. Upon request, we can supply a quotation of the most suitable tools required for use on this machine.